At RoboBusiness2025, I met Bren Pierce, CEO of Kinisi Robotics. This interview was recorded on October 16, 2025

“We’re starting with simple tasks to bootstrap our foundational model.”

– Bren Pierce, CEO and Founder of Kinisi Robotics

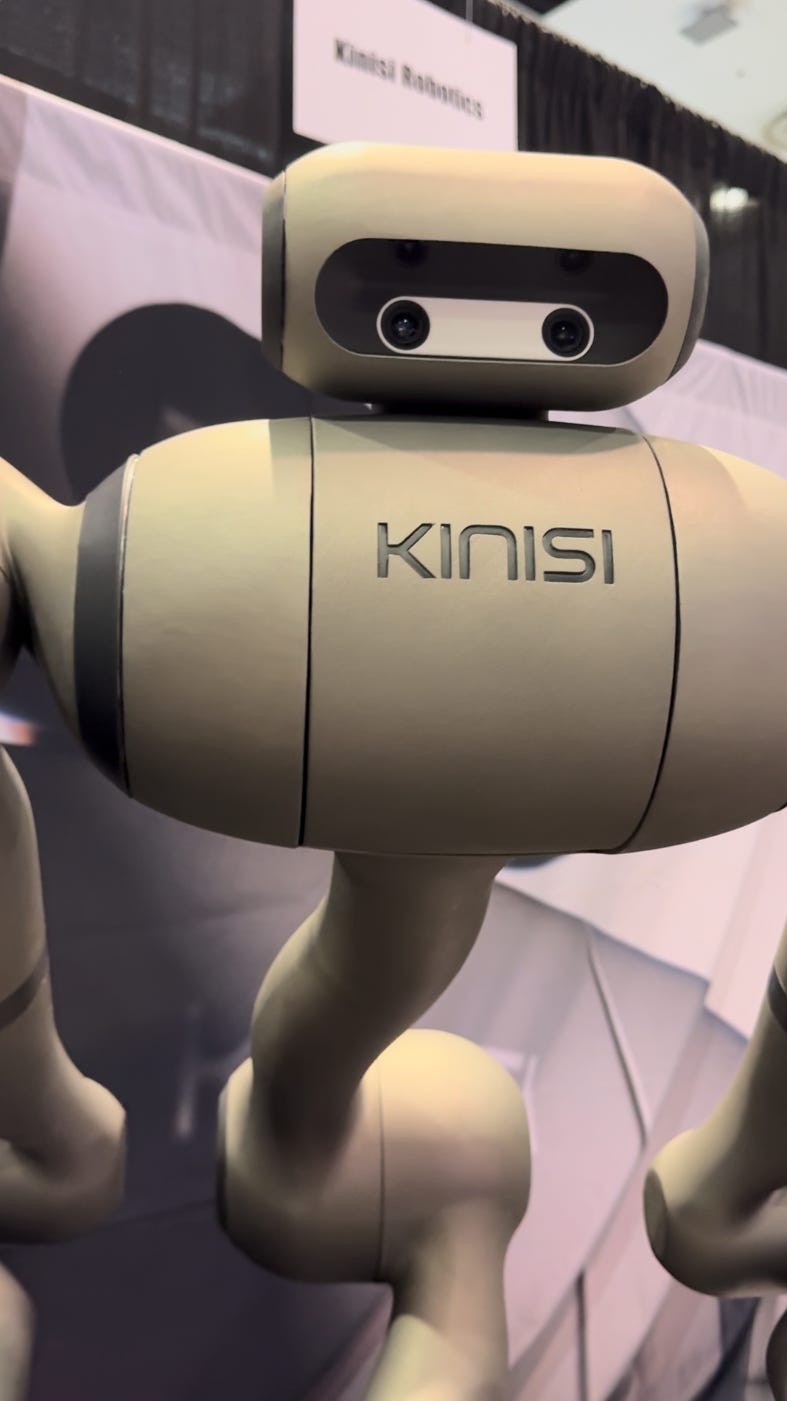

In an era where humanoid robots are drawing headlines for dancing, sprinting, or flipping switches with eerily human hands, Kinisi Robotics is charting a different course — one grounded not in spectacle, but in reliability.

Their flagship robot, KR‑1, isn’t designed to wow audiences. It’s built to show up, lift crates, and do the work — safely, efficiently, and without a marketing team on standby.

“Our KR‑1 humanoid robot is designed for the warehouse and factory space,” says CEO Bren Pierce, who believes the future of robotics is less about human mimicry and more about human utility.

A Humanoid That Moves with Purpose

KR‑1 walks the line — metaphorically — between form and function. Its upper body takes design cues from humans, making it naturally suited to environments built for people. But instead of legs, KR‑1 moves on a wheeled base — a choice driven by engineering pragmatism.

“Warehouses are flat,” Pierce points out. “We don’t need 14 motors if two will do.”

That simple equation shapes the entire robot. KR‑1 is engineered for tasks like lifting and delivering crates, picking objects, and navigating complex indoor spaces — not to imitate human movement, but to solve real problems quickly and affordably.

Field-Tested, Factory-Tough

Where many robots are still making the leap from lab to warehouse, KR‑1 is already being tested across pilot facilities in Europe and North America. These trials are more than checklists — they’re stress tests, designed to challenge the robot’s autonomy, perception, and endurance in messy, real-world environments.

This field data is central to Kinisi’s iterative design process. Instead of engineering in a vacuum, the company is learning from operators on the ground — and adapting quickly.

“Robots are in pilot facilities in Europe and America,” Pierce confirms. “We’re learning what’s needed, not just what’s possible.”

Safe by Design

Working alongside humans comes with responsibilities, and KR‑1 takes that seriously. The robot uses advanced sensors, full-environment perception, and soft-force control systems to ensure smooth, predictable behavior around people.

“It can see people and will slow down and stop when they get close.”

Full safety certification is underway, with initial deployments in semi-separated zones. The vision is clear: human-robot collaboration without compromise.

And unlike cages or warning zones, KR‑1’s behavior is built to be fluid and situational, adapting in real time to the pace and flow of human workers.

Start Small, Scale Smart

KR‑1 begins with a focused skillset — lifting, moving, delivering. But it’s designed to grow. Kinisi’s strategy is to earn trust through reliability, then expand the robot’s capabilities as operators discover new use cases.

That “bootstrapping” approach mirrors how many of today’s biggest tech platforms started: do one job extremely well, then build from there.

“We’re starting with simple tasks to bootstrap our foundational model.”

This is robotics not as a spectacle, but as infrastructure — steady, quiet, and transformative over time.

In Good Company, With a Different Approach

Kinisi doesn’t see itself as racing against other humanoid pioneers — but rather contributing a new piece to the puzzle.

While companies like Agility Robotics, Figure AI, and Tesla explore bipedal mobility and expressive motion, Kinisi is doubling down on operational dependability, minimal complexity, and deployment readiness. It’s not a question of right or wrong — just a difference in what’s needed first.

If we want robots to become part of the workforce, they need to show up ready to do the job. KR‑1 was built to do exactly that.

Vocabulary Key

Mobile manipulator: A robot that combines a moving base with robotic arms, able to navigate and interact with its environment.

360-degree perception: Sensor fusion that gives the robot awareness of its surroundings in all directions.

Human-safe design: Engineering principles that prevent robots from harming or startling nearby workers.

Pilot deployment: A real-world test run, often used to refine robot behavior before full rollout.

Bootstrapping model: A strategy that starts with simple, reliable tasks and scales capabilities gradually.

FAQs

Is KR‑1 a fully humanoid robot? It’s humanoid in function, not form. The robot has arms and a head-like sensor suite but uses wheels instead of legs for efficiency.

What can it do today? Lift crates, pick and place items, deliver payloads across a facility, and avoid obstacles and people in real time.

How is it trained or programmed? Operators can train KR‑1 through demonstration, reducing the need for specialized code or robotic expertise.

Is it safe to work near? Yes. KR‑1 uses real-time human detection and soft-stop behavior. Safety certification is expected within the next year.

Where is it being used? Pilot programs are active in Europe and the U.S., primarily in warehouses and light manufacturing environments.

Further Reading

NextTech Today. Kinisi Robotics Focuses on Wheeled Humanoids for Industry

5 Questions with Kinisi CEO Brennan Pierce – The Robot Report

Agility Robotics and the Digit roadmap

Humanoids in 2025: Hype or hardware? – Humanoid Guide

#HumanoidRobotics #WarehouseAutomation #IndustrialRobotics #LogisticsTech #RoboticsInnovation #MobileManipulators #RobotDeployment #FactoryAutomation #RobotDesign #PhysicalAI